The following products and services are part of our proposal:

- Development and series support

- Electronic component production in SMT (Surface Mount Technology)

- Electronic component production in THT (Through Hole Technology)

- Device assembly and programming

- Assembly testing (AOI, In-Circuit-Test, EOL)

- Other services

Development and series support

Since 2022, ESCD has expanded its offering for customers by a development department, where both is possible independent development at customer's order and close collaboration with the customer's development department.

| Hardware | Software | |

|---|---|---|

| • Power- and microelectronic | • Embedded Control in C and C++ | |

| • Industrial control devices | • Microcontroller ARM (M0, M3, M4) | |

| • Controller, communication | • Python | |

| • Sensors | • CAN | |

| • Output stages, switching power supply | ||

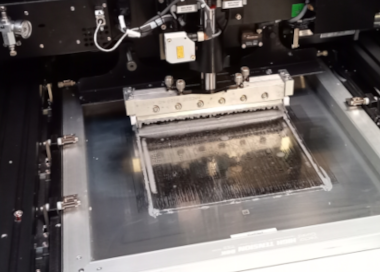

SMT production and mounting

We mount microtechnology in our machine park by means of three ultramodern mounting lines:

In every line one ASMPT-DEK stencil printer equipped with SPI (Solder-Paste Inspection) - System ASMPT Process Lens is deployed for utmost performance and premature error detection. After SMD-mounting by three ASMPT SIPLCE SX2 V3 the assemblies undergo the reflow soldering systems by ERSA. The line last put into service uses the Kurtz Ersa HOTFLOW THREE with 26 heating zones.

Electronic component production in THT

For THT assembly one ERSA Versaflow for selective joints and two Powerflow N2 wave soldering machines of the latest generation are available to us. A fully automated circulation system ensures fast processing.

Our THT production mounts complex mixed assemblies (with SMD and wired components) as well as power assemblies at customers' order. Mixed assemblies in THT and SMT are soldered RoHS compliant. For the conversion from leaded to lead-free we offer our customers both soldering methods.

Automatic double-sided surface preservation is done by two coating machines from Rehm, the Protecto XP with a RDS 3000 drying oven each and an integrated reversing station.

Device assembly and programming

As EMS provider we also offer device assembly. This is done by professional assemblers. Following this, the operating software is installed.

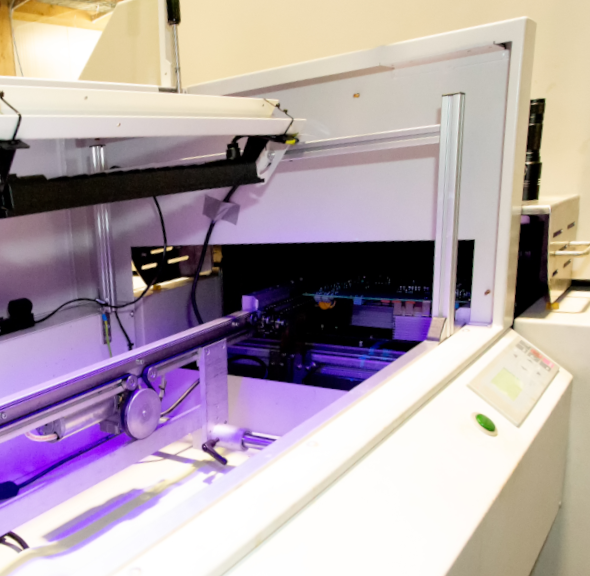

Assembly testing (AOI, In-Circuit-Test, EOL tester)

The SMT production lines terminate with a new AOI-System OptiCon AdvancedLine from Goepel for 3D-inspection after the soldering process. One highlight is the shadow-free inspection and measurement from 360 degrees at constant resolution and definition.

By high resolution this optical systems ensure maximum inspection safety for highest quality of the produced assemblies at ESCD's.

Our testing area holds three ICT systems which are able to conduct in-ciruit tests as well as functional tests and programming of all established program modules. For the EOL (end-of-line) test we furthermore provide the construction of customer-specific test rigs.

Other services

In addition to that we provide:

- Material procurement and stockpiling

- Repair and conversion services

- Analysis of field returns

- Training courses for Certified IPC specialists

- 3D printing

- CAD design of mechanical components for assemblies